Health assessment and diagnostics of boilers, analyses, and conceptual work

Fabryka Kotłów SEFAKO S.A. provides comprehensive services in terms of the health assessment and diagnostics of:

- water boilers

- steam boilers

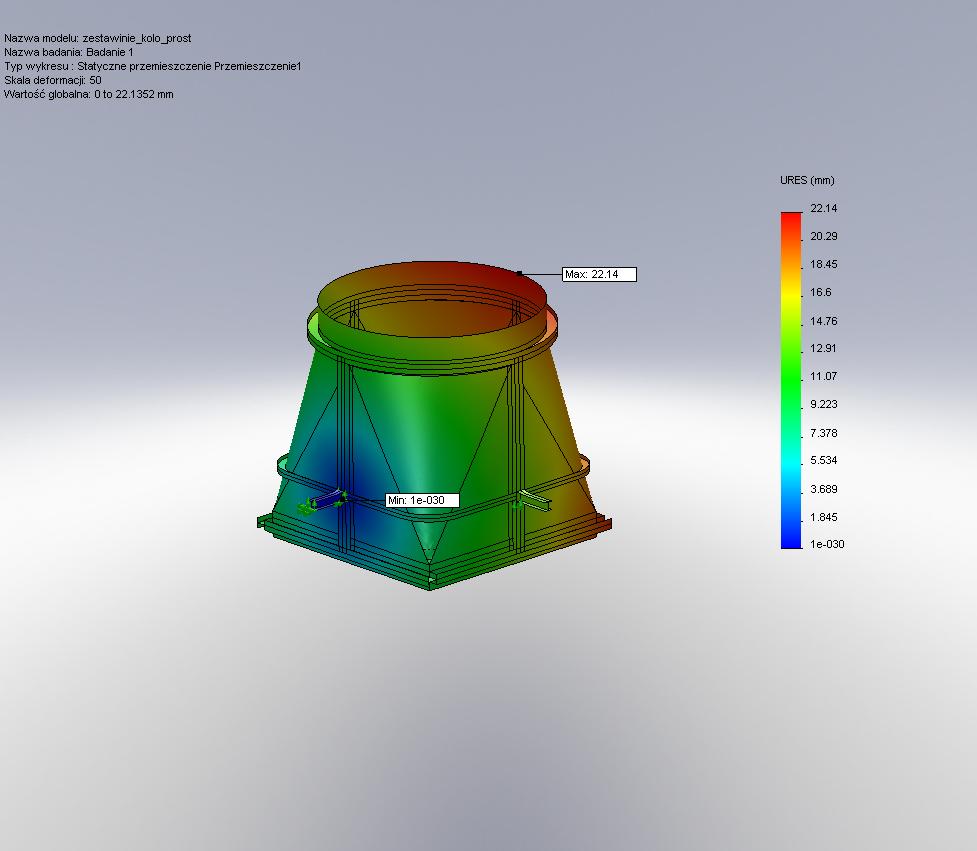

- boiler plant equipment

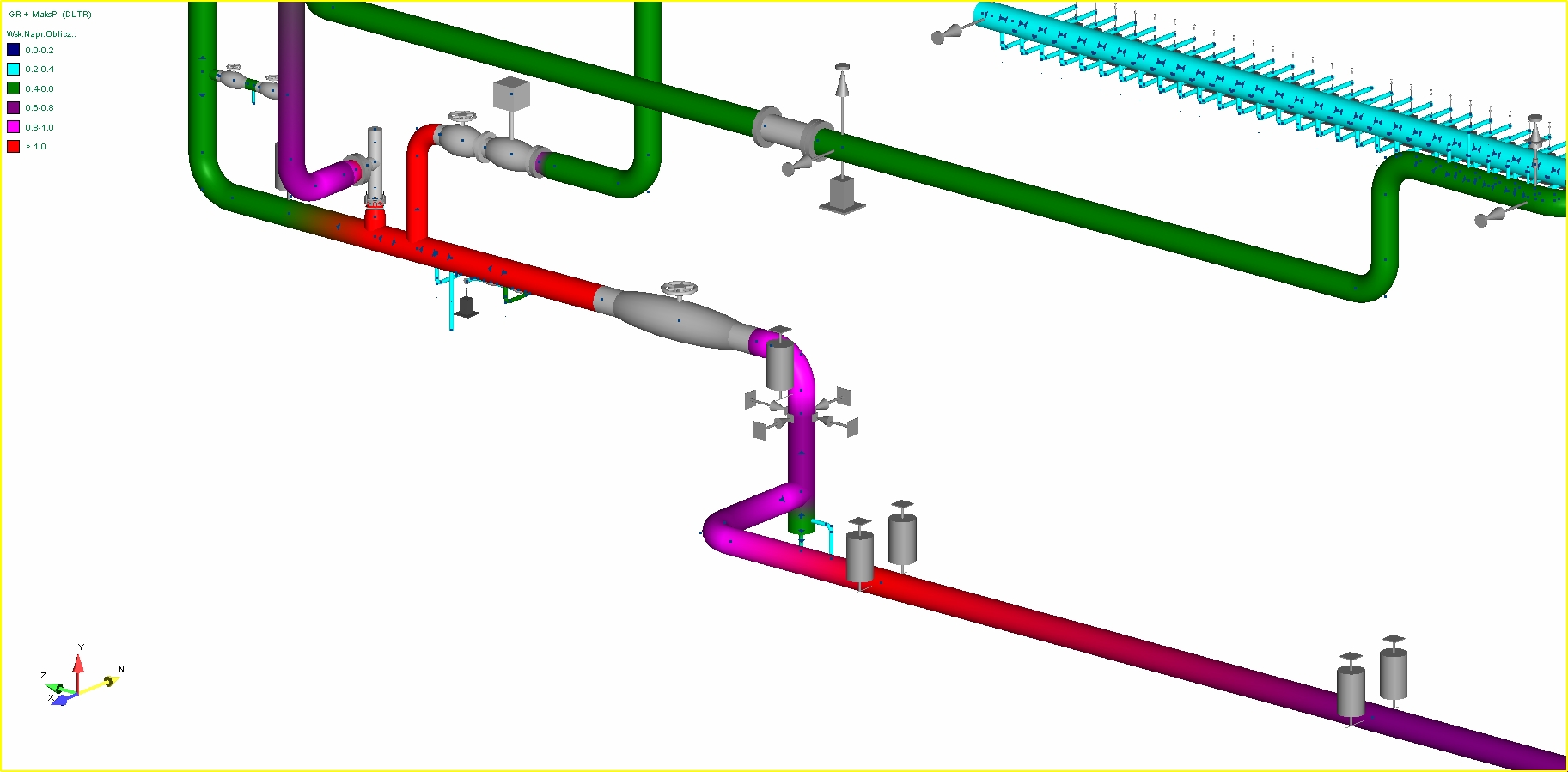

- pipelines and their suspension structures

- pressure vessels

SEFAKO provides technical testing to assess the health of boiler components, forecast their safe operation, and evaluate the service life of materials.

A suitable health assessment allows the informed scheduling of overhauls and retrofitting, hence avoiding unexpected failures and standstills.

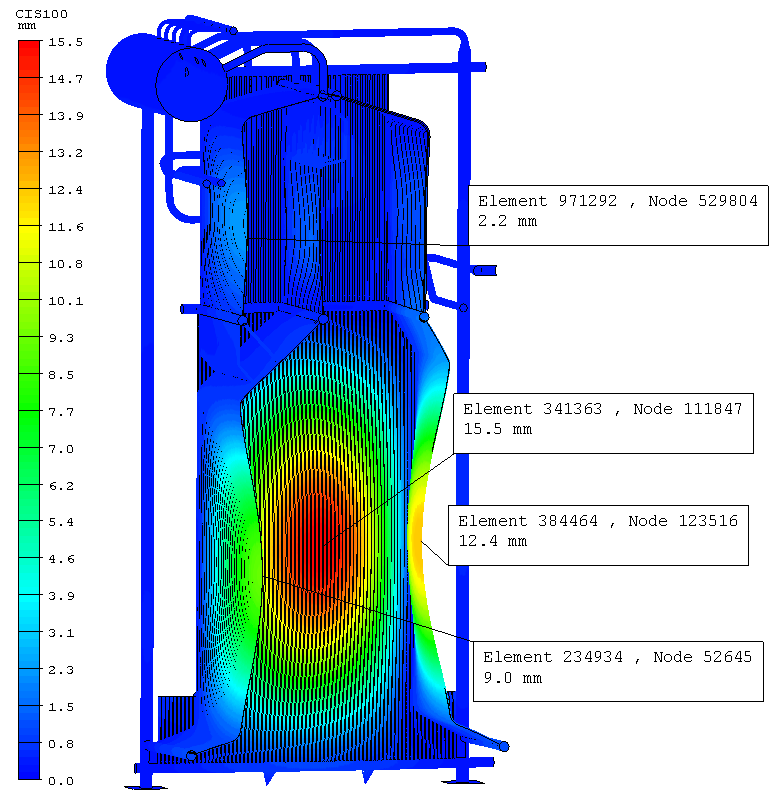

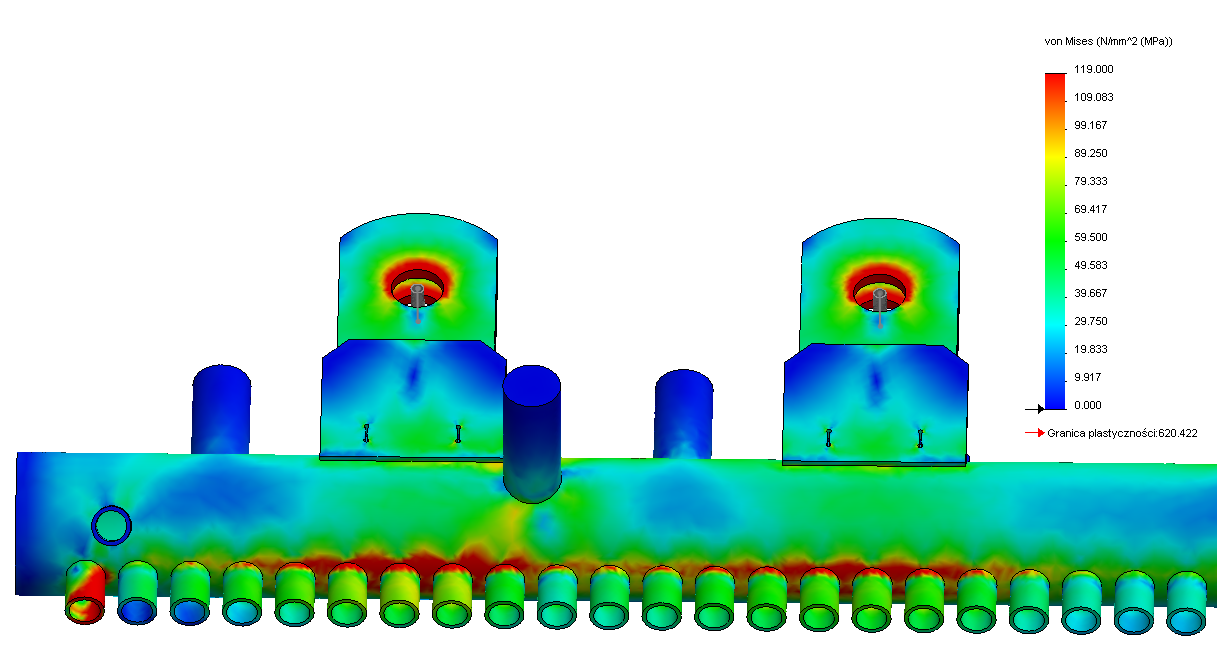

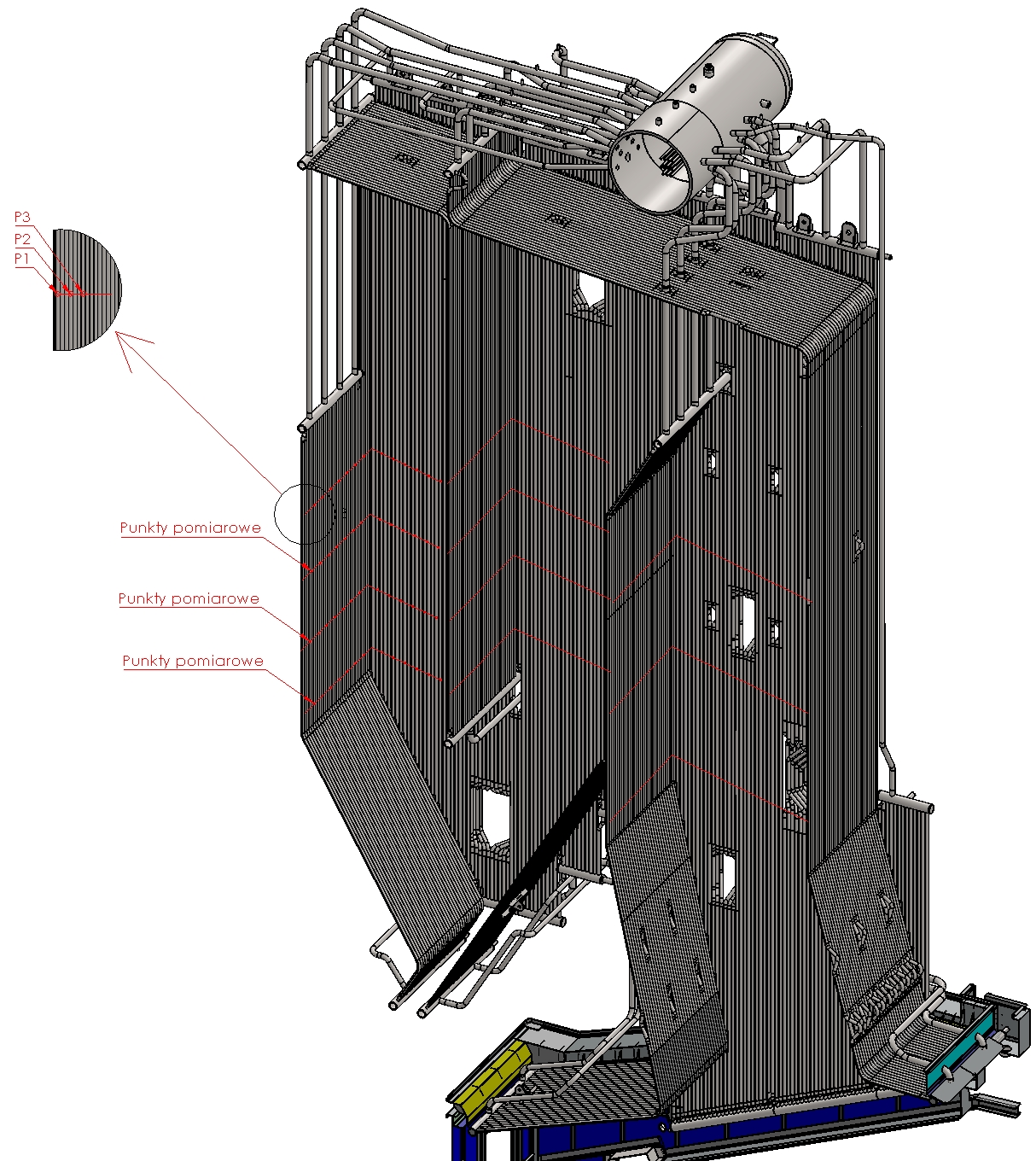

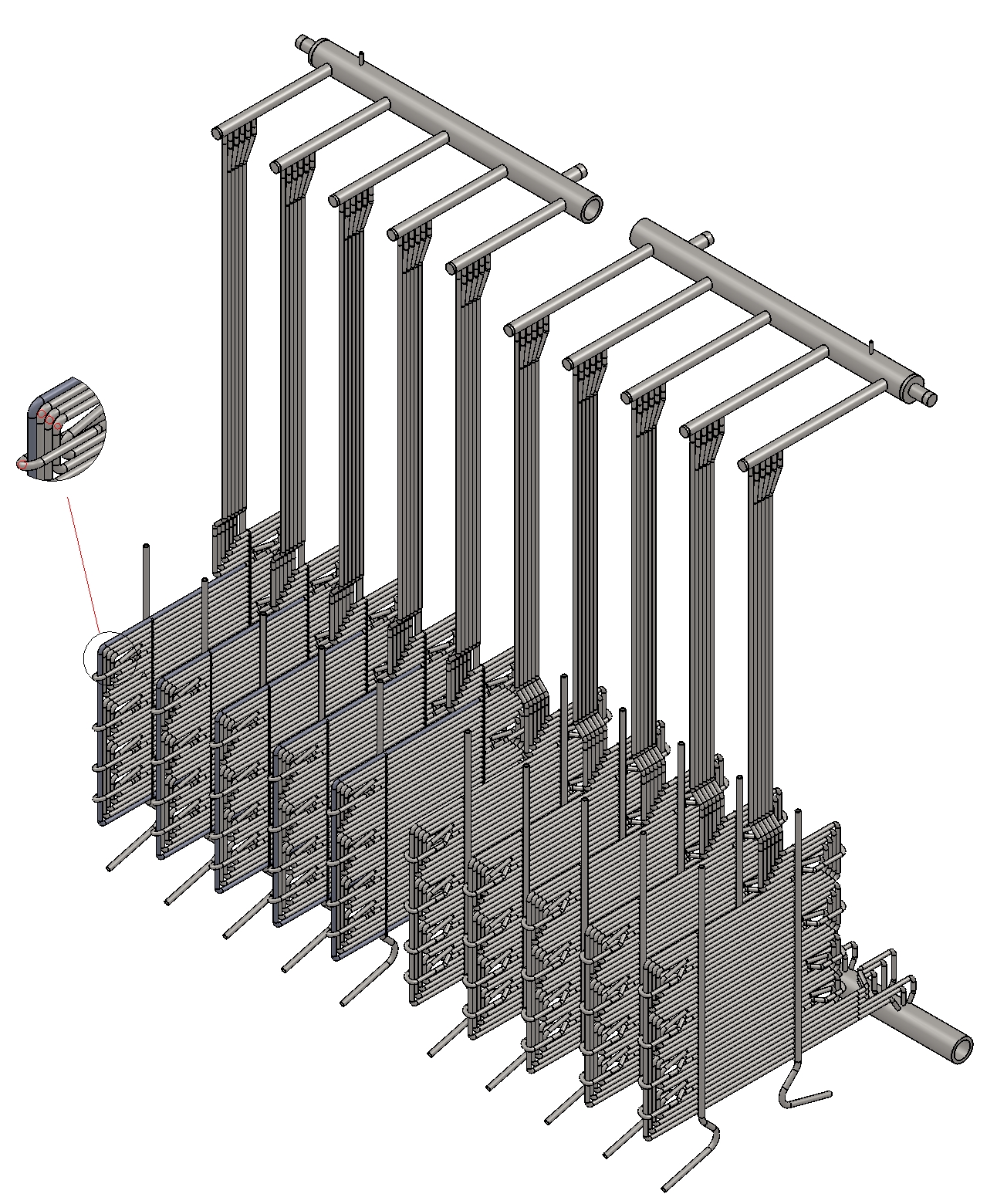

The components of all active boilers suffer the effects of erosion. However, availability is one of critical operating parameters of a boiler. The condition of pressurized and non-pressurized boiler components largely depends on the boiler operating parameters, quality of operation and maintenance, boiler design and materials, operating conditions, fuel, etc. Each boiler component, including the superheater, evaporator, economizer, and boiler drum, vary in operating conditions and are exposed to different wear patterns. A good health assessment of a boiler helps in the informed scheduling of overhauls and retrofitting.

.jpg)

SEFAKO S.A. services:

NDT (non-destructive testing)

Ultrasonic thickness measurement

Ultrasonic weld testing

Magnetic particle inspection

Penetrant inspection

Replica metallographic examination

Portable hardness machine testing

Visual inspection

Chemical composition testing of metals

Endoscopic examination

DT (destructive testing)

Material and weld tensile testing

Material and weld bend testing

Material and weld impact testing

Material and weld fracture testing

All tests and inspections undertaken by SEFAKO S.A. serve as data inputs for diagnosing the health of specific boiler components, piping, suspension structures and boiler plant equipment.